Induction Motor & Starting Methods

In Industries one of the common motor type is Induction motor . Its also reffered to as squirrel cage motor . Induction motor can be either single phase or 3 phase type and comes in different ratings. In this article more focus is on 3 phase type of induction motor.

In Induction motor there is stator winding and a rotor winding. When power given to the stator a back emf is induced in the rotor. The back emf tries to oppose the cause which is the rotating magnetic field generated in the stator. the sychronous speed of the rotating magnetic field of stator

is (120 *f)/p where f is the supply voltage frequency and p is the number of poles. The speed of the induction motor rotor will be slightly less than that of this speed due to slip

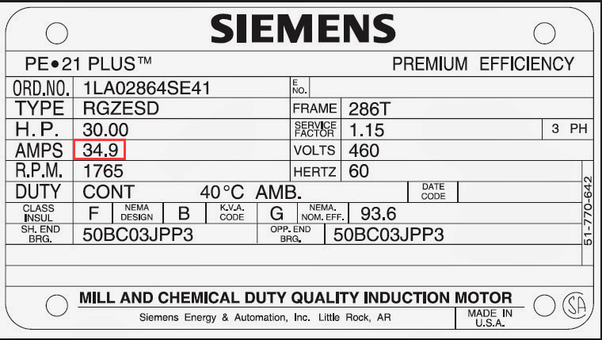

Below shows the picture of a typical nameplate found on Induction Motor

Multiple information regarding its rating is available in from the nameplate.

Starting Schemes for Induction Motors

Below are the popular starting methods for Induction motor(3 phase type)

DOL Starting (Direct On Line Starting)

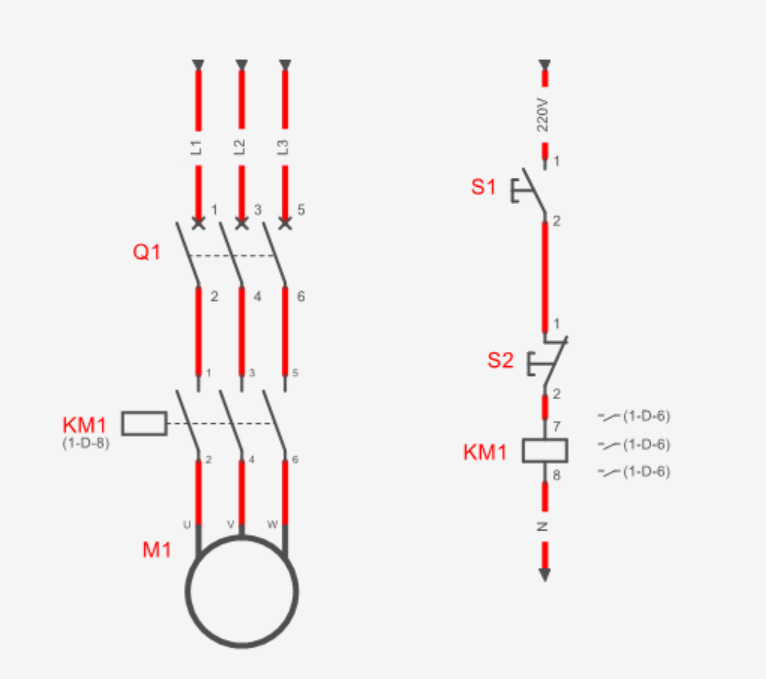

In this scheme 3phase power is directly supplied to the motor via a circuit breaker or contactor. The staring current may be 4 to 7 folds in this case. For smaller sized motors with no need for ramp start or speed control this scheme is normally used. Usually upto to 5.5 Kw motors rather star delta starting this scheme normally employed when there is no need for speed control. But if the start stop frequency is higher like in some production or cyclic operations better to opt vfd to save power.

Below shows the typical connection drawing.

Star Delta Starting

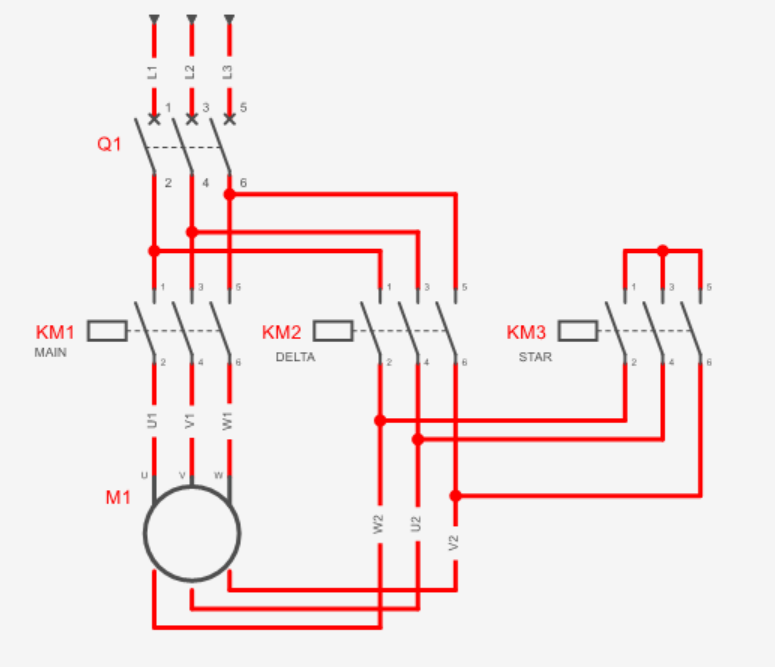

As mentioned above typically 7.5kw onwards in applications in which cost is main concern and required for speed control does not exist like fixed speed geared motor or agitator or fan/pump applications this scheme of starting is opted.

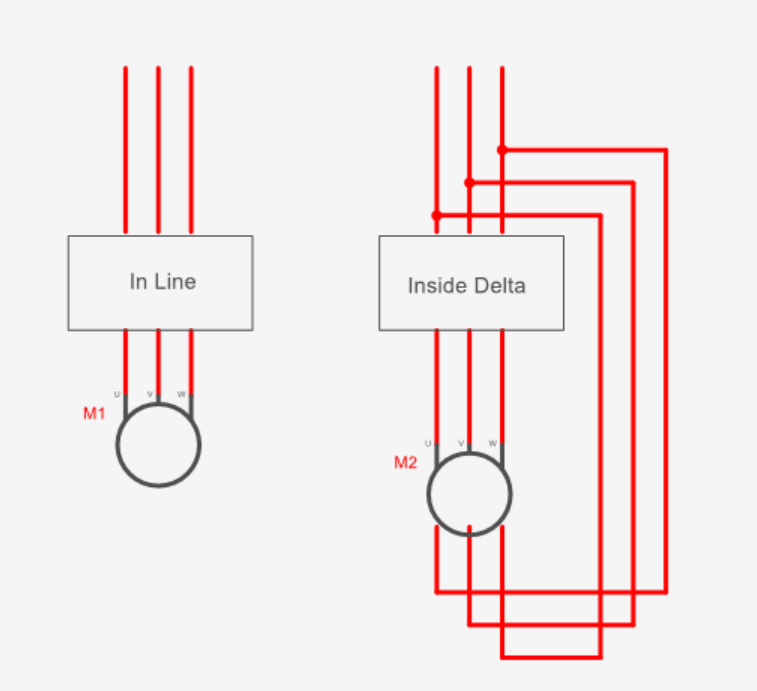

In this scheme the during the staring the motor will be in star connection and using contactor logic after a predefined time the power circuit is switched to delta connection. When compared to DOL starting there reduction in starting current spike in this case.

Usually the power circuit comprise of

- MPCP( Motor protection circuit breaker

- Three contactors ( Main, Delta, Star)

- Thermal overload relay

- Control circuit

Below shows picture for typical star delta wiring. A timer is often used to control the switching time from Start to Delta

Soft Starter

Softstarter is a power electronic device which helps in a ramp start/stop for the induction motor. in this scheme without changing the frequency , only the the voltage is ramped up from a minimum voltage to rated voltage.

VFD(Variable Frequency Drive / Inverter)

This is the most accepted way in this era for controlling an induction motor

VFD as mentioned above stands for Variable Frequency Drive

In VFD the input 3 phase power is first rectified to DC Power. This DC power inturn is inverted to AC. But during the invertion the output voltage frequency is adjustable typically upto 600Hz. The IGBT devices are used for this purpose which has a switching frequency in KHz range. Sinusoidal pulse width modulation techniques are used for invertion.

usually two methodologies are used for this

V/F control

In V/F Control there is characteristic relation between Voltage and frequency. As the voltage increases, Frequency also increases in a pattern. there is linear as well as curves optimized for pump and variable torque applications.

Vector Control

Vector control is more sophisticated control in which the motor load current has two aspects. the magnetizing component and and the working components. Vector control provides good starting torque at lower rpm

Typical VFDs have digital input output control terminals for various user defined commands such as forward, reverse, multispeed etc

Also new generation VFDs are equipped with latest industrial field bus interfaces such as profinet, modbus canopen etc.

Typical VFD have a keypad display through which the parameters are configured. The same display can be used to operate the VFD and also monitoring and perform diagnostics. Detailed article in VFD will be available in which you can understand the basic procedure for setting up VFD, switchgear selection, commissioning steps as well as troubleshooting in the event of a problem

Recent Comments